Our goal is to help you better understand Failure Mode and Effects Analysis (FMEA) by offering insights and practical tips based on years of experience. Whether you’re new to doing root cause analyses or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

Dealing with potential failures and mitigating their impacts forms the core of reliability engineering. A systematic tool known as Failure Mode and Effects Analysis (FMEA), is a method that provides a path to improved reliability and enhanced performance.

Failure Mode and Effects Analysis, commonly abbreviated as FMEA, is a structured, step-by-step, proactive approach to identifying and analyzing all the conceivable failures in a product, process, design, or service. Conceived during the 1950s within the aerospace industry, this technique has since become a valuable tool across multiple industries.

A ‘failure mode’ in FMEA refers to the way in which a component, subsystem, system, process, or design could potentially fail to meet the expected performance standards. These failure modes are then evaluated for their potential effects on the system or end-users, establishing a comprehensive understanding of the potential risks associated.

The ultimate objective of FMEA is to quantify and prioritize the risks associated with these identified failure modes to guide the improvement efforts. It does this by assessing three key metrics for each failure mode: severity (the potential impact of the failure), occurrence (the likelihood of the failure happening), and detection (the ability to discover the failure before it becomes an issue).

An integral part of FMEA is the calculation of the Risk Priority Number (RPN), which is a numerical value derived from the severity, occurrence, and detection ratings. This RPN allows for the ranking of failure modes in terms of their potential risk, assisting in the prioritization of improvement actions.

FMEA, empowers organizations to anticipate potential problems and implement corrective measures before any failure occurs. This makes it a powerful technique in enhancing the reliability, safety, and quality of products or processes, ultimately leading to better customer satisfaction and cost savings.

Imagine an automotive manufacturer planning to release a new car model. An FMEA could be performed on the braking system:

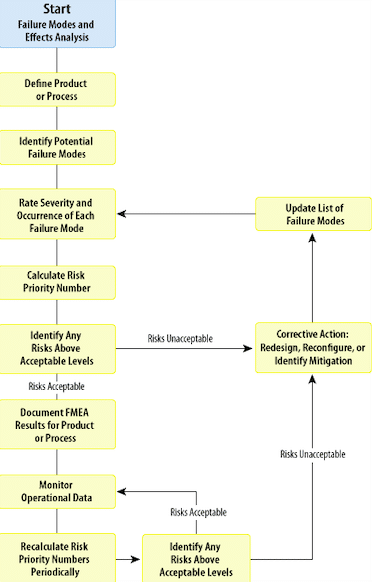

It presents a structured way to identify what could go wrong (failure modes), understand the consequences (effects), and estimate the gravity (severity). Here’s a step-by-step guide to performing an FMEA:

Begin by choosing a process that has exhibited problems or is typically troublesome in your organization or industry. This selection lays the groundwork for the analysis to follow.

Organizational leadership should offer a clear project charter, setting the stage for the analysis. The team, led by a facilitator appointed by the leadership, consists of individuals directly involved in the process under analysis. This team should include representatives from diverse areas like design, manufacturing, quality control, sales, customer service, and more.

Delineate the process steps in a way that ensures everyone on the team fully comprehends the process under scrutiny. This clarity sets the stage for a thorough analysis.

With the process clearly defined, have the team brainstorm potential failure modes for each step. The people working closely with the process are often best placed to spot these possible issues.

Not all problems are created equal. Some issues might occur frequently or have a more substantial impact on product quality or safety. These issues warrant priority in your improvement efforts.

The team then devises strategies to reduce the likelihood of failure modes or mitigate their effects. These changes could relate to design alterations, process adjustments, or enhancement of detection mechanisms.

Like any improvement initiative, it’s crucial to measure the success of the implemented actions. The team should assess whether the changes made have effectively reduced the risk of failure or its impact.

Once the team completes the analysis, they create an FMEA table detailing potential failures, their effects, and associated severity, occurrence, and detection rankings. These rankings range from 1 to 10, with 1 indicating a low impact and 10 showing a high impact.

By multiplying these rankings (Severity x Occurrence x Detection), the team obtains a Risk Priority Number (RPN), which serves as a guide to prioritize work based on the severity and likelihood of failure. Any recommended actions should then address these prioritized risks.

The living FMEA document, continually updated, serves as an invaluable resource for the development of derivative products and a repository of organizational knowledge. Critical characteristics, regulatory compliance needs, process controls, and other relevant data are also recorded here, offering a comprehensive view of potential risks and their mitigation strategies.

In a comprehensive FMEA study, every potential failure is assessed and evaluated based on three fundamental criteria. These criteria allow the team to grasp the significance of each failure mode, how frequently it’s likely to surface, and how readily it could be detected before resulting in any adverse impact.

The team participating in the FMEA study must reach a consensus on the ranking for severity, occurrence, and detection for every failure mode. While the FMEA process is primarily qualitative in nature, it is beneficial to utilize any available data to substantiate the decisions regarding these rankings. This makes the analysis more precise and helps to mitigate any potential biases or assumptions. Remember, the ultimate goal of FMEA is to prioritize risks and facilitate the development of effective strategies to manage them.

Failure Mode and Effects Analysis (FMEA) is a robust and systematic approach to anticipate, prioritize, and mitigate risks. It helps organizations preemptively address possible hitches in their processes or products, paving the way for higher safety, improved quality, and increased customer satisfaction. Despite its complexity, the returns it offers in risk mitigation are invaluable, making FMEA a tool of choice for organizations keen on proactive problem-solving and continuous improvement. It’s not just about solving problems – it’s about predicting and preventing them. That is the power of FMEA.

At Reliability, we’re here to help guide your journey through such complex yet rewarding methodologies. Empower your organization by learning more about Root Cause Analysis, as well as other valuable tools and strategies for achieving and maintaining quality and reliability. Get in touch with us today to see how we can facilitate your journey to improved reliability and heightened business performance.

I hope you found this guide to Failure Mode and Effects Analysis insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit Reliability Resources.